Why use a low level access platform?

According to OSHA, ladders continue to be the leading cause of slips, trips and fall on jobsites.

- More than 500,000 people receive emergency room treatment from ladder-related injuries every year.

- More than 300 of these falls end up being fatal

- OSHA believes 100% of all ladder accidents could be prevented if proper attention to equipment and climber training were provided.

- According the Bureau of Labor Statistics, 50% of all ladder-related accidents were due to individuals carrying items as they climbed.

- The percentage is even greater in the construction trades. If those statistics aren’t enough, the U.S. Consumer Products Safety Commission reports that more than 90,000 people are treated in emergency rooms each year as a result of ladder-related injuries.

- They can make jobs easier, quicker and more efficient.

- Low level access machines provide a safe and secure environment for operatives to work at height.

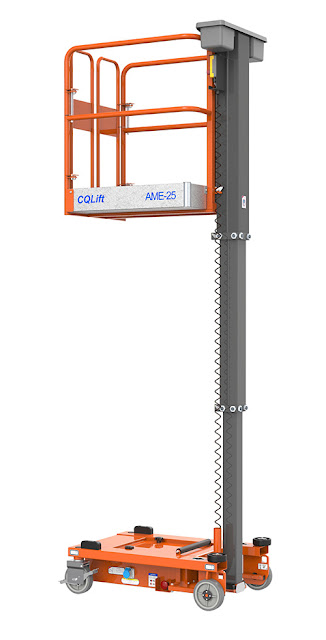

- Low level access platforms include both push around (manual) platforms as well as some self propelled models (electric / battery powered).

- Most are fitted with non-marking tyres to help protect floor finishes but can still be operated outside in certain conditions.

- Productivity – Low level access machines combine the flexibility and quick set up benefits of ladders and steps with enhanced safety and an improved worksite environment. This maximises productivity, especially when working in confined spaces. Setup and relocating times are often shorter than with scaffold systems.

- Flexibility – Low level access machines can be used to carry out a wide range of maintenance and construction tasks and allow operatives to keep tools and materials close-by, boosting

Comments

Post a Comment